Maximize Your Manufacturing Potential with CNC Machines from roc-tech.com

In today's rapidly evolving industrial landscape, CNC machines have emerged as a game-changer for businesses seeking efficiency and precision in their manufacturing processes. At roc-tech.com, we understand the needs of modern businesses and are proud to offer a comprehensive selection of CNC machines for sale. This article explores the multitude of benefits that CNC technology can bring to your operations and highlights why roc-tech.com stands out as your go-to source for top-quality machinery.

Table of Contents

- What is CNC Technology?

- Advantages of CNC Machines

- Types of CNC Machines Available

- Why Choose roc-tech.com for Your CNC Needs?

- How to Select the Right CNC Machine

- Conclusion

What is CNC Technology?

CNC stands for Computer Numerical Control, a technology that enables the automated control of machine tools through a computer interface. This method uses precise coding to dictate the movements of machinery, allowing for high levels of accuracy and repeatability. Unlike traditional manual machines, CNC machines can operate without continuous human intervention, freeing up valuable resources while significantly increasing production efficiency.

Advantages of CNC Machines

There are numerous advantages to incorporating CNC machines into your manufacturing process, including:

- Increased Precision: CNC machines can produce parts with an incredibly low tolerance level. This precision is crucial for industries that rely on exact measurements, such as aerospace, automotive, and medical.

- Enhanced Productivity: Automation reduces production time, allowing businesses to fulfill larger orders faster and more efficiently than manual processes.

- Consistency: Once a CNC program is set, it can produce the same part multiple times without variability, ensuring uniform quality across large batches.

- Reduced Labor Costs: Automation can significantly reduce the need for manual labor, lowering overall labor costs while reallocating workforce resources to other critical areas.

- Complex Designs: CNC machines can create intricate designs and shapes that would be extremely difficult or impossible to achieve with manual techniques.

Types of CNC Machines Available

At roc-tech.com, we pride ourselves on providing diverse options to suit various industries and applications. Here are some common types of CNC machines available:

- CNC Mills: Perfect for producing flat parts, CNC mills can cut a wide range of materials from metal to wood with great precision.

- CNC Lathes: These machines are utilized for creating cylindrical parts and can perform various operations like cutting, drilling, and sanding.

- CNC Routers: Ideal for a variety of materials, CNC routers are used for cutting, engraving, and producing signs.

- CNC Plasma Cutters: Used to cut metals, these machines offer a cost-effective solution for precision cutting.

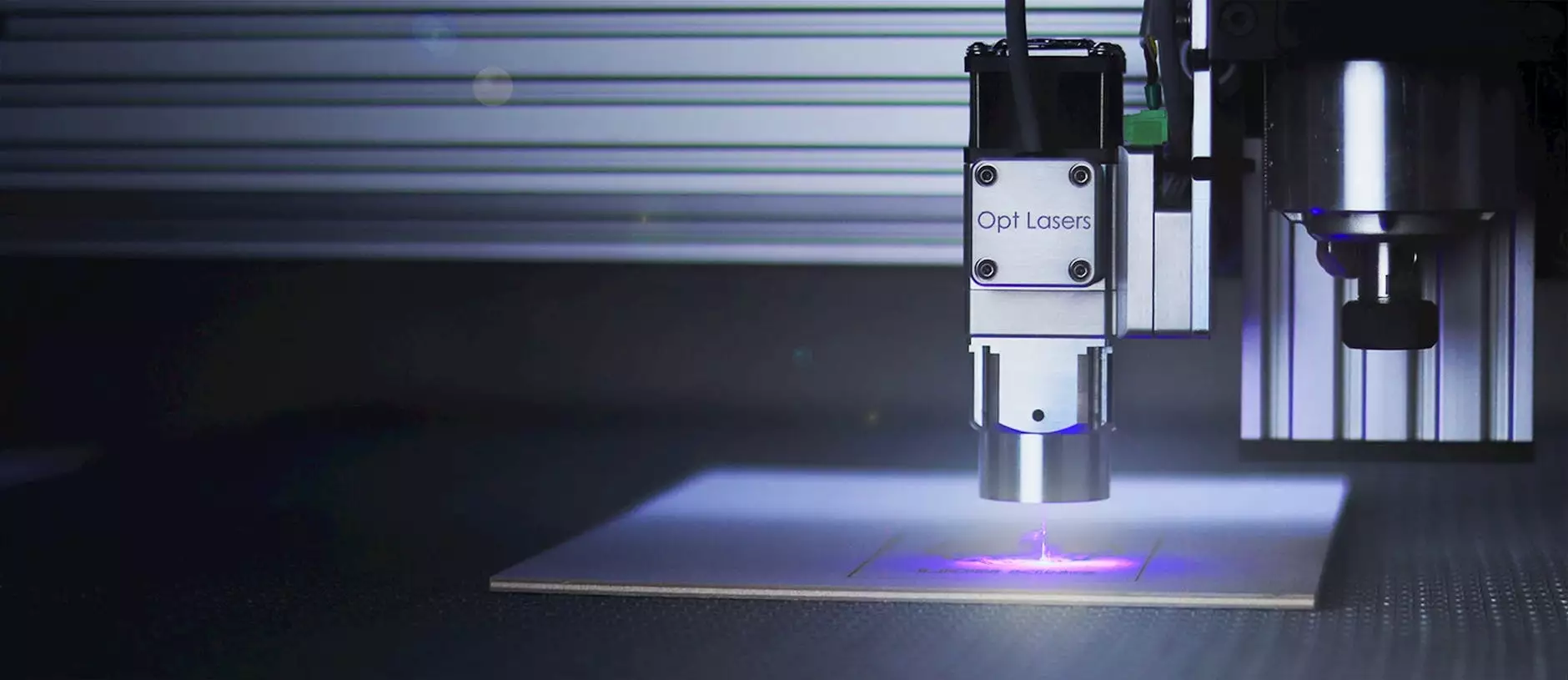

- CNC Laser Cutters: High precision and speed make CNC lasers highly valuable for detailed cuts and engravings.

Why Choose roc-tech.com for Your CNC Needs?

When considering your options for CNC machines, roc-tech.com stands at the forefront for several compelling reasons:

- Diverse Selection: Our extensive inventory features a wide range of CNC machines tailored to meet the demands of every sector.

- Quality Assurance: We prioritize quality and reliability, ensuring that every machine meets stringent standards for performance and durability.

- Competitive Pricing: At roc-tech.com, we believe that superior technology should be accessible. Our pricing reflects a commitment to value.

- Expert Consultation: Our knowledgeable team is available to assist you in selecting the perfect machine that fits your specific requirements.

- After-Sales Support: Our relationship doesn’t end with the sale. We offer comprehensive support services to help you maximize your investment.

How to Select the Right CNC Machine

Choosing the right CNC machine can be a daunting task, but there are several factors to consider that can simplify the decision-making process:

- Identify Your Needs: Outline the specific tasks you need the machine to perform, considering factors like material type, complexity of design, and tolerances required.

- Consider Your Budget: Set a budget that includes the cost of the machine, installation, and potential maintenance expenses.

- Space Availability: Assess your workshop or factory space. Make sure you have enough room for the machine and its operational needs.

- Explore Features: Look into the features offered by different models. Options like automation, programming capability, and safety features can significantly impact efficiency.

- Visit roc-tech.com: Our website provides in-depth details and specifications for each CNC machine, aiding your deliberation process.

Conclusion

CNC technology is revolutionizing the manufacturing sector, and with roc-tech.com, you have access to high-quality machines that can enhance your production capabilities. This investment in technology can yield significant returns by improving precision, reducing costs, and increasing efficiency. Explore our offerings at roc-tech.com, and allow us to support you towards achieving manufacturing excellence.

For more information, visit us today at roc-tech.com!